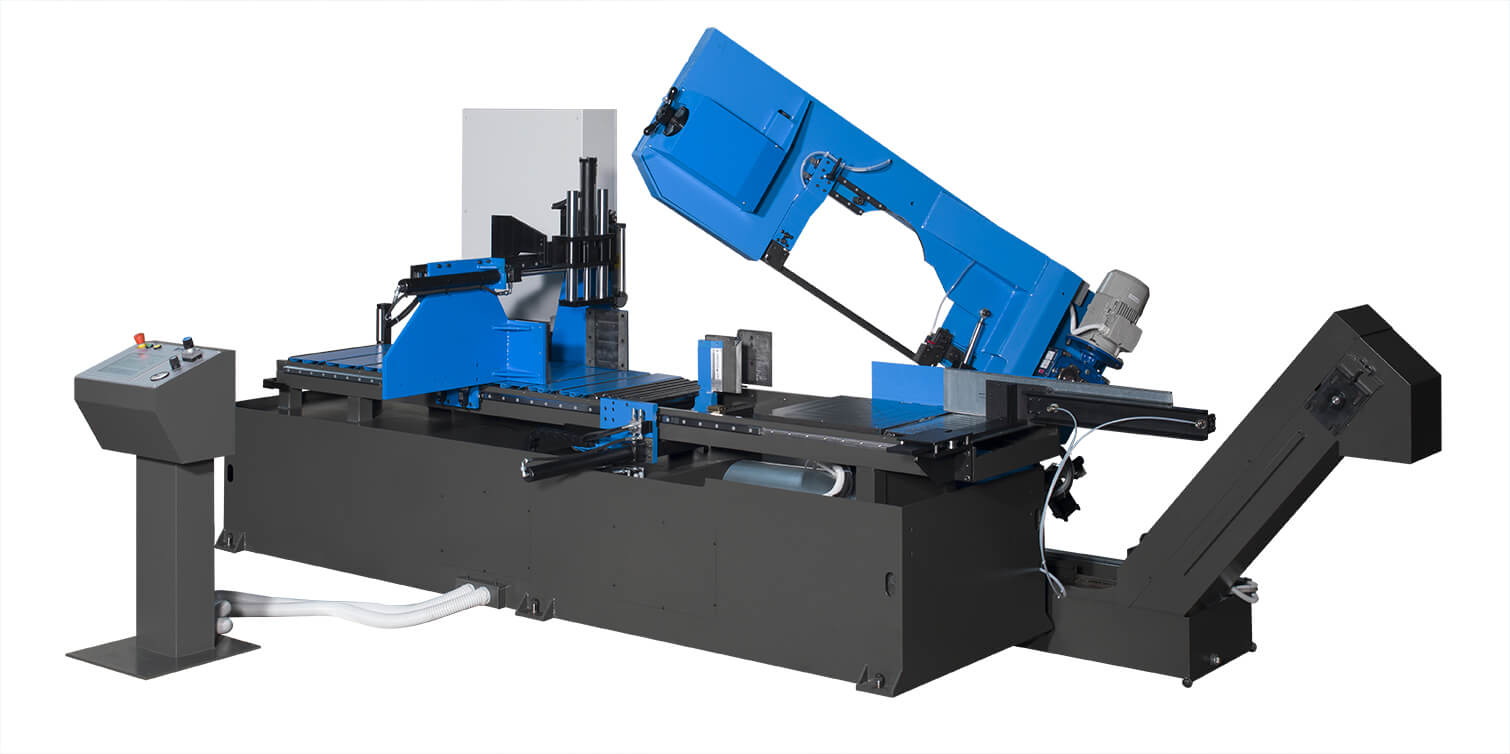

61.41 A DI 3R

» Automatic band saw 61.41 A DI 3R CNC is designed for metal structure workshops, pipe bundles, etc. with the possibility of rotating 60º right and left.

CNC control of all machine functions with the possibility of storing up to 30 cutting programs. This cutting programming includes both lengths and angles.

61.41 A DI 3R

» Automatic band saw 61.41 A DI 3R CNC is designed for metal structure workshops, pipe bundles, etc. with the possibility of rotating 60º right and left.

CNC control of all machine functions with the possibility of storing up to 30 cutting programs. This cutting programming includes both lengths and angles.

TECHNICAL FEATURES

Saw bow and base in welded structure.

Offsetting cylinder for saw bow downfeed.

Hydraulic band tensioning with manual regulation.

Band detensioning with hydraulic control panel stop for longer band life.

Adjustable saw guidepost slides made from WIDIA.

Fast downfeed and raising controlled by a touch probe.

Feed movement and saw bow rotation controlled by brushless motor.

Possibility of external connection via RS232.

Infinitely-adjustable cutting feed.

Saw motor speed with digital frequency converter.

Electronic display of the cutting angle.

Adjustable pressure depending on the section and type of material: the feed rate increases or decreases proportionally to the cutting resistance.

Possibility of connection with beam drilling system. Low voltage electrical installation as per CE standards.

More information

Fill in the form to download the product sheet.

| MODEL 61.41 A DI 3R | ||||||

|---|---|---|---|---|---|---|

| CUTTING CAPACITY IN MM. | 90º | 45ºR | 60ºR | 45ºL | 60ºL | |

|

410 | 410 | 320 | 410 | 330 | |

|

410 | 410 | 300 | 410 | 310 | |

|

610x410 | 460x250 | 320x180 | 460x270 | 320x180 | |

| Blade dimensions LxWxH | mm. 5200x34x1,1 | |||||

| Blade speed | mt./l' 15-80 | |||||

| Fast downfeed | mm/l' 3500 | |||||

| Cutting downfeed | mm/l' 0-2000 | |||||

| Cutting pressure | bar 0-20 | |||||

| Motor power | Blade | Kw. 3 | ||||

| Hydraulic unit | Kw. 1,5 | |||||

| Cooling pump | Kw. 0,12 | |||||

| Feeding carriage | Kw. 0,75 | |||||

| Swarf conveyor | Kw. 0,09 | |||||

| Working plane height | mm. 870 | |||||

| Shipping dimensions | mm. 5400x2270x2250 | |||||

| Machine dimensions | mm. 5930x3290x2550 | |||||

| Weight | Kg. 3880 | |||||

TECHNICAL FEATURES

Saw bow and base in welded structure.

Offsetting cylinder for saw bow downfeed.

Hydraulic band tensioning with manual regulation.

Band detensioning with hydraulic control panel stop for longer band life.

Adjustable saw guidepost slides made from WIDIA.

Fast downfeed and raising controlled by a touch probe.

Feed movement and saw bow rotation controlled by brushless motor.

Possibility of external connection via RS232.

Infinitely-adjustable cutting feed.

Saw motor speed with digital frequency converter.

Electronic display of the cutting angle.

Adjustable pressure depending on the section and type of material: the feed rate increases or decreases proportionally to the cutting resistance.

Possibility of connection with beam drilling system. Low voltage electrical installation as per CE standards.

OPTIONAL ACCESSORIES

- Automatic saw bow rotation device with DC motor

- Saw deflection control device.

- Hydraulic bundle clamping device.

- Dry cutting device.

- Swarf extractor.