Innovation

Since its foundation, the company FAT has devoted a significant part of its resources to research, development and innovation (R&D&i), being able to study, design and manufacture from small metal cutting machines, to large facilities. Only in this way are we able to adapt to all types of customers, from small workshops to large factories.

Projects

When we have to face a project to create a machine adapted to our customers, we do it by personalising the project by placing the customer at the centre. Only in this way can we offer a product adapted to each customer.

Our projects include the study of the customer’s workflow. This is the only way we can determine the suitability of each machine. SME customers, such as workshops, do not have the same needs as those with a factory manufacturing locomotives or agricultural machinery.

The FAT team is also in charge of how the machines are going to work mechanically to make them more efficient and to consume less. The technological evolution, the miniaturisation of the parts and the creation of oils and lubricating fluids for machinery have all allowed us to develop our machines to become better and more efficient and to reduce their consumption.

Another aspect that we evaluate in the project is the location and assembly study. It is important to know where this machine will be working and where the customer plans to install it. Because, depending on its location in the factory or workshop where it is installed, its consumption may increase or the operating experience may be affected.

Projects

The implementation of these projects includes:

- Workflow studies.

- Machining studies.

- Assembly studies.

- Customised machine studies.

- Standard machine studies.

- Location studies.

- Financial studies on depreciation.

Fat machines in the field of steel, aluminium, pvc, brass and bronze

The innovations by FAT also cover metals such as steel, aluminium, brass or bronze, in addition to PVC. In this field, we have worked on studies to create machines such as:

FAT machines for steel

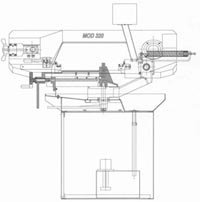

- Standard cuttinc disc machine

- Standard band saws

- Special cuttinc disc machine

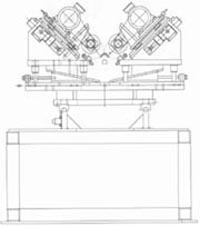

- Machines for pipe ends and solid ends

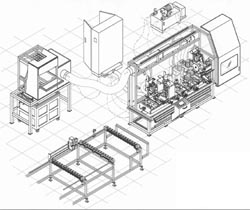

- Intelligent warehouses for sheet metal bars and coils

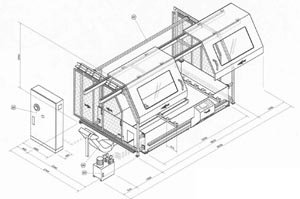

- Combined CNC cutting and machining systems

FAT machines for aluminum

- Machines for cutting, punching, drilling, threading and milling special parts from bar material or cast parts.

- Linear transformers for the manufacture of aluminium carpentry accessories.

- Intelligent warehouses for profiles, dies or screws

- Complete turnkey plants for the manufacture of aluminium windows.

PVC, brass and bronze

FAT machines for PCV, brass and bronze, materials for which we develop manual, semi-automatic and automatic cutting lines with automatic or CN control, with or without chargers.