370 A 60º & CNC

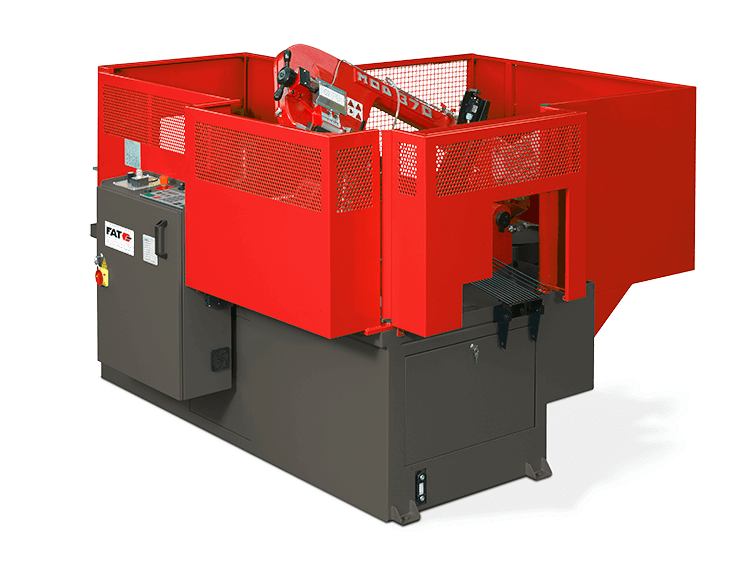

» The 370 A 60º is a hydraulic machine that, together with the characteristics of the semi-automatic and the advantage of automatic material feeding, is ideal for cutting large series with small and medium dimensions, of the most varied sections, with an angle of up to 60º, suitable for use in mechanical and carpentry workshops that demand quality work and good speed of execution.

370 A 60º & CNC

» The 370 A 60º is a hydraulic machine that, together with the characteristics of the semi-automatic and the advantage of automatic material feeding, is ideal for cutting large series with small and medium dimensions, of the most varied sections, with an angle of up to 60º, suitable for use in mechanical and carpentry workshops that demand quality work and good speed of execution.

TECHNICAL FEATURES

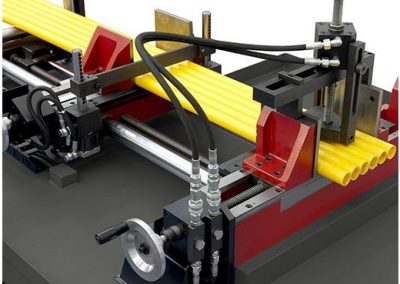

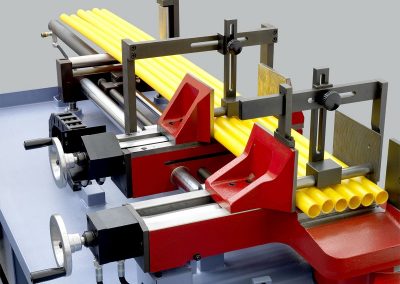

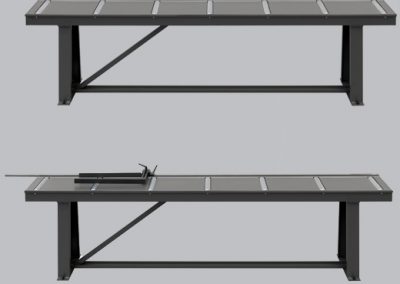

Base in welded and standardised structure. Tempered aluminium saw bow, mounted on tapered roller bearings. Gear unit consisting of hardened and ground gears. Spheroidal cast iron vice unit, hydraulic control unit. Adjustable band guidepost slides made from WIDIA. Tension of the mechanical band controlled by a limit switch. Powered band cleaning brush. Fast downfeed and outfeed controlled by a touch probe. Cylinder placed at the front to increase the strength of the system and ensure Biger durability of the band. Swarf extractor (included in the CNC model). Adjustable pressure depending on the section and type of material. The feed rate increases or decreases proportionally to the cutting resistance. Material feeding carriage with possibility of transversal oscillation to facilitate bar feeding. Automatic mechanical length stop, controlled by encoder (included in the CNC model). Digital display to enter the length of the part (only AUTOMATIC). CNC that controls all machine functions, except for the pivot of the saw bow, with the possibility of storing the cutting programs (included in the CNC model). Infinite “INVERTER” electronic blade speed variator (included in the CNC model). Low voltage electrical installation according to CE standards. Embossed finish.

More Information

Fill in the form to download the product sheet.

| MODEL 37 A 60º & CNC | ||||

|---|---|---|---|---|

| CUTTING CAPACITY IN MM. | 90º | 45º | 60º | |

|

280 | 225 | 140 | |

|

240 | 215 | 95 | |

|

330x240 | 230x140 | 140x130 | |

| blade dimensions LxWxH | mm. 3120x27x0,9 | |||

| Standard blade speed | mt./l' 35-70 | |||

| Optional blade speed | mt./l' 20-100 | |||

| Working table height | mm. 835 | |||

| Standard Motor | Kw. 0,9-1,5 | |||

| Optional Motor | Kw. 1,1 | |||

| Fast downfeed | mm/l' 3500 | |||

| Cutting downfeed | mm/l' 0-200 | |||

| Cutting pressure | bar 5-20 | |||

| Scrap length | mm 200 | |||

| Hydraulic pump motor power | Kw. 0,75 | |||

| Coolant pump | Kw. 0,12 | |||

| Machine Dimensions | mm. 3000x1900x1900 | |||

| Shipping dimensions | mm. 2200x1500x1700 | |||

| Weight | Kg. 945 | |||

TECHNICAL FEATURES

Base in welded and standardised structure. Tempered aluminium saw bow, mounted on tapered roller bearings. Gear unit consisting of hardened and ground gears. Spheroidal cast iron vice unit, hydraulic control unit. Adjustable band guidepost slides made from WIDIA. Tension of the mechanical band controlled by a limit switch. Powered band cleaning brush. Fast downfeed and outfeed controlled by a touch probe. Cylinder placed at the front to increase the strength of the system and ensure Biger durability of the band. Swarf extractor (included in the CNC model). Adjustable pressure depending on the section and type of material. The feed rate increases or decreases proportionally to the cutting resistance. Material feeding carriage with possibility of transversal oscillation to facilitate bar feeding. Automatic mechanical length stop, controlled by encoder (included in the CNC model). Digital display to enter the length of the part (only AUTOMATIC). CNC that controls all machine functions, except for the pivot of the saw bow, with the possibility of storing the cutting programs (included in the CNC model). Infinite “INVERTER” electronic blade speed variator (included in the CNC model). Low voltage electrical installation according to CE standards. Embossed finish.

OPTIONAL ACCESSORIES